How to Choose an Inline Filter – Physical Connections

Inline Filter Physical Connections

Inline Filter Physical Connections

There are many considerations in carefully choosing an inline filter. Common choices focus on the expected particle load and the chemical exposure. Sample tests will show that it works in the intended operating environment. However, critical options exists with the physical connections on in-line filters. This post will review connection choices for inline filters: barbed, threaded, Luer and push-in connections.

Barbed Connections

A barbed connection has one or more ridges or barbs. This is the section of an inline filter pushed into a tube during installation. Pushing a tube end over a barb causes it to expand and then relax to its original size on the far side of the barb. Relaxation of the tubing around the cylindrical surface behind the barb provides a connection seal. Gripping forces of the barb need to be greater than pull off forces on the tubing.

Barb features that are critical to gripping force:

- Barb shape

- Number of barbs

- Spacing of multiple barbs

- The outer diameter (OD) of the barb relative to the ID of the tubing

- How the barbed fitting was made

Sharper barbs grip better but can cut into soft tubing. Steeper, deeper barbs also grip better but can be difficult to install and replace. Single barbs work better with soft, stretchy tubing. Multiple barbs (double and triple barbed) work over a wider range of hardness (durometer) but work best with harder tubing materials. How suppliers make barbed connection ports is important because minimizing or eliminating parting lines eliminates potential leak paths.

Sharper barbs grip better but can cut into soft tubing. Steeper, deeper barbs also grip better but can be difficult to install and replace. Single barbs work better with soft, stretchy tubing. Multiple barbs (double and triple barbed) work over a wider range of hardness (durometer) but work best with harder tubing materials. How suppliers make barbed connection ports is important because minimizing or eliminating parting lines eliminates potential leak paths.

What is durometer?

Durometer is a reference measurement for material hardness based on its resistance to penetration. You will usually see durometer describing the hardness of polymers, elastomers and rubbers. The lower the tube durometer the softer it is and the more likely a barbed connection is a good choice.

Threaded Connections

Machinery ports use threaded connections most of the time. Because miniature fitting connections handle liquids and gases, they need to be leakproof. There are many standards for threads but most fluidic and pneumatic threaded ports use tapered threads. The most common tapered threads are NPT or BSPT. It is the combination of tapered thread and thread sealant that provides a leakproof seal. Installation without over tightening is necessary for a good seal. Please keep an eye out for my future blog on threads and all the standard thread types.

Luer Connectors

Luers use conical or tapered connectors. Connected male and female Luers create secure, detachable, leak-proof connections without an O-ring or gasket. Producers make Luer connectors in a wide variety of configurations. Luer connections are commonly used in medical applications.

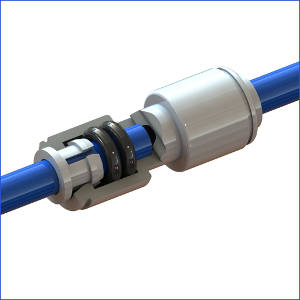

Push-in Connectors

Push-in connectors are leak resistant because they use built-in O-ring seals. This type of connector has built-in metal teeth that grip the tubing. In order for a push-in connector to function properly, the tubing needs to be soft enough for the teeth to grip but not so soft that the tubing bends instead.

Putting It All Together

This is only a quick look at inline filter connections. Barbs, threads, Luers and push-ins all have detailed technical specs but you can safely use these tips:

- Barbed connectors should be matched to the tubing

- Threaded connectors should have the right threads, sealant and correct installation

- Luer connectors are very flexible but their size limits their uses

- Push-in connectors provide quick, easy installation but should be matched to the tubing

- Adapters provide options for in-line filter installation.

Look for our upcoming blog article about the adoption of standing desks in the ISM office:

There is More to Standing Desks than Just Standing

Previous posts in our How to Choose an In-line Filter series: