What is Kynar® Plastic? — PVDF Plastics for Flow Control Parts

Last updated on February 23, 2023

Learn why Kynar® and PVDF plastic might be the best material choice

Kynar® is Arkema's trade name for their PVDF plastic. PVDF or polyvinylidene difluoride plastic is a tough, stable, very non-reactive thermoplastic.

PVDF, an engineered plastic with exceptional properties such as strength, durability, abrasion resistance, and low permeability, is a preferred material in medical applications due to its high-temperature resistance and compatibility with chemical sterilization methods such as autoclaving and gamma radiation. Additionally, it is an environmentally sustainable option, as it is recyclable.

What is PVDF plastic?

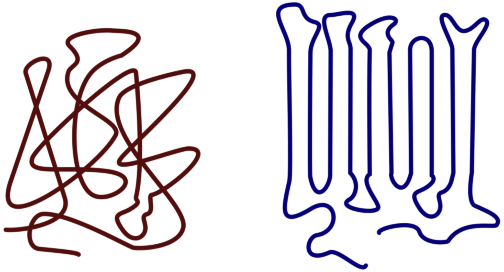

Technically, PVDF is a semi-crystalline high-performance thermoplastic.

Semi-crystalline plastics

Semi-crystalline plastic materials have a very organized molecular structure and sharp melting points. This means that they do not gradually soften as their temperature increases. Instead, they stay solid until their melting point is reached. When they are hot enough, semi-crystalline plastics quickly change from solids into low viscosity or thin liquids that flow easily.

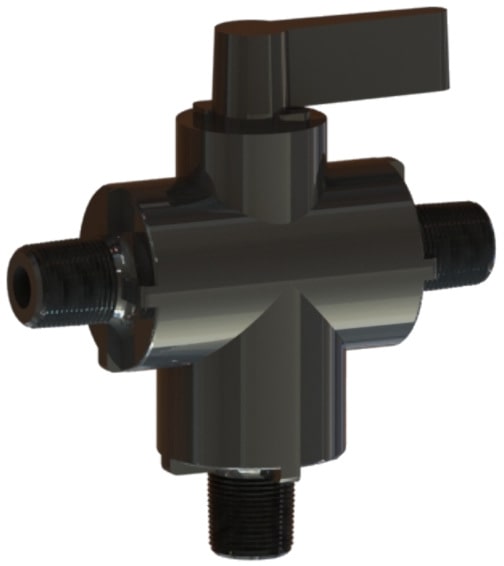

PBV3 series three-way ball valves from ISM are available in black Kynar® (PVDF) plastic >>

thermoplastics

Learn more about amorphous vs. semi-crystalline thermoplastics at Redwood Plastics and Rubber >>

Typically, semi-crystalline thermoplastics performs at temperatures between -40F to 180F (40C to 82C), but the specific melting point depends on the type of plastic.

Thermoplastics

Thermoplastics are useful for making products because they can be heated until they melt and flow. After cooling, thermoplastics become hard again.

This cycle of melting, reforming and cooling can be repeated again and again. Injection molding is a production process that takes advantage of this. It can be used to quickly and economically produce large numbers of consistently high-quality thermoplastic parts.

Learn more about thermoplastics at AZO Materials >>

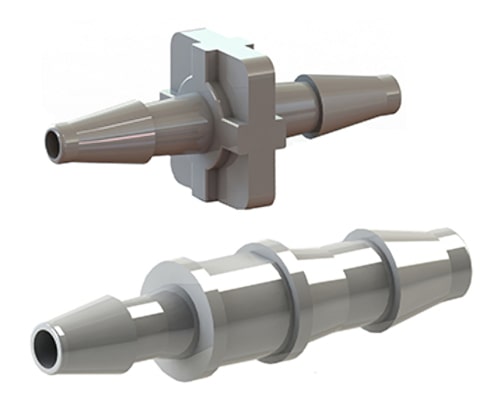

Kynar® (PVDF) plastic luer fittings are available at ISM >>

Fluoropolymers

PVDF is also a fluoropolymer. Fluoropolymers are polymers or plastics that have multiple carbon-to-fluorine bonded sections inside each molecule. Fluoropolymer plastics are very resistant to solvents, acids, and bases.

PVDF is also FDA compliant and completely non-toxic. This means it can be used in repeated contact with food.

Kynar® (PVDF) plastic tubing from ISM >>

- Bases

- Ozone

- Alcohols

- Mineral acids

- Organic acids

- Halogenated solvents

- Aromatic hydrocarbons

- Aliphatic hydrocarbons

- Oxidizing environments

Check out the Chemicals and chemistry resources section at the end of this article >>

There is more information about these chemical groups below plus links to in-depth descriptions at highly reputable sources.

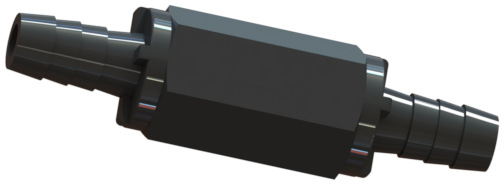

Black Kynar® (PVDF) plastic CVSC series lightweight spring-loaded check valves from ISM >>

- Low weight

- Recyclable

- High Strength

- Good toughness

- Weather resistant

- High heat resistance

- Good electrical insulator

- Good chemical resistance

- Slippery or low coefficient of friction

- Low permeability to most gases and liquids

- Good endurance

- Radiation resistant

- Mechanically strong

- High abrasion resistance

- Good resistance to stress cracking

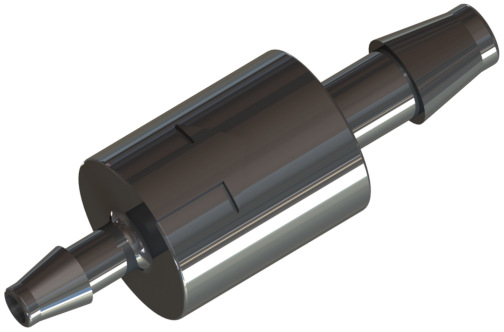

Kynar® (PVDF) plastic CVS series high strength spring loaded check valves from ISM >>

Environmental stress cracking is when a thermoplastic fails after it has been exposed to certain chemicals. This failure is not the direct effect of being exposed to a particular chemical. Instead, stress cracking is caused by a combination of

- A plastic’s susceptibility to stress cracking

- Its exposure to a chemical that causes stress cracking

- The mechanical stresses caused by pulling or tugging on the material

Chemicals that can cause stress cracking include detergents, surfactants, lubricants, oils, ultra-pure water and plating additives such as brighteners and wetting agents.

Learn more about stress cracking at ISM’s Chemical Compatibility Chart landing page >>

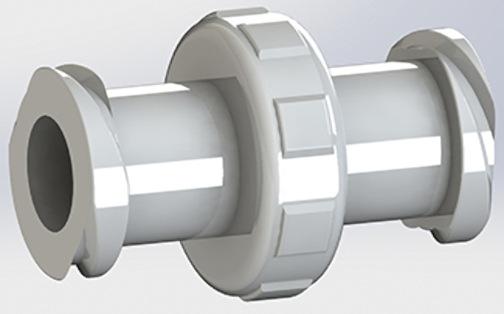

Kynar® (PVDF) plastic VC straight tube connectors from ISM >>

PVDF is a strong, tough, durable plastic. Its abrasion resistance is greater than other plastics and even some metals. It does not leach any chemicals and is highly resistant to a broad range of chemicals.

Using Kynar and PVDF plastic components is the right choice when it is important to prevent system failures due to weathering, stress cracking, abrasion and chemical corrosion.

References for much more in-depth chemical and technical details about PVDF plastic

- Check out the Polyvinylidene Fluoride (PVDF) Complete Guide at SpecialChem >>

- Check out the PVDF Properties and Their Values pate at SpecialChem >>

- Get a copy of our PVDF (Kynar®) Chemical Compatibility Chart >>

Back to the “What chemicals are PVDF plastics resistant to?" section of this blog post >>

Chemicals and chemistry resources

Alcohols are organic compounds with a hydroxyl group attached to one end of the molecule. Hydroxyl groups are one hydrogen atom bonded or attached to an oxygen atom.

Get more information at the Alcohol page from Encyclopædia Britannica >>

Bases are the opposite of acids. Like acids, bases also tend to be very corrosive depending on the specific chemical and how concentrated it is. Lye is a strong base that most people are familiar with.

Get more information at the Base page from Encyclopædia Britannica >>

Sulfuric acid, hydrochloric acid and nitric acid for example. Mineral acids are acids made from an inorganic compound. These acids easily dissolve in water and are highly acidic.

Get more information at the What is a Mineral Acid page from ThoughtCo >>

Carboxylic acids and sulfonic acids are organic acids. These acids are organic compounds that have acidic properties: liquids, corrosive and so on. Organic acids tend to be weak acids and do not dissolve completely in water.

Get more information at the Organic Acid page from Wikipedia >>

Chloroform, carbon tetrachloride, and methylene chloride are examples of halogenated solvents. These solvents are compounds that contain halogen atoms (see below).

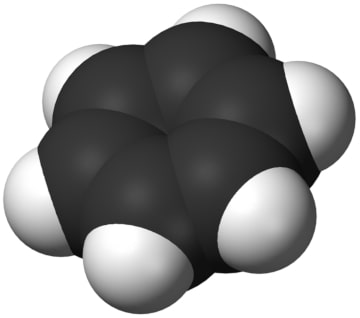

Benzene is an aromatic hydrocarbon. These chemicals are organic compounds that contain one or more benzene rings. A benzene ring is a hexagonal ring of six carbon atoms.

Get more information at the Aromatic Hydrocarbon page from Wikipedia >>

Methane, acetylene, and ethylene for example. Aliphatic hydrocarbons are organic compounds whose atoms do not link together to form a ring.

Get more information at the Aliphatic Hydrocarbon Definition page from ThoughtCo >>

Oxygen, hydrogen peroxide and the halogens are examples of oxidizers. In the Earth's atmosphere, iron is converted to iron oxide or rust because there is plenty of oxygen available.

Get more information at the Oxidizing Agent page from Wikipedia >>

Halogens are the group non-metallic elements that includes fluorine, chlorine, bromine and iodine. These elements are poisonous and are highly chemically reactive.

Get more information at the Halogen page from Wikipedia >>

Back to “What chemicals are PVDF plastics resistant to?" section of this blog post >>