Plastic Diaphragm Check Valves – Check Valves Part II

Last updated on February 9, 2023

Plastic diaphragm check valves are highly adaptable and economical

An introduction to diaphragm check valves

In my previous post about check valves, I provided a brief overview of check valves. Continuing on that subject, what I want to talk about next is a very pragmatic type of check valve used for miniature pneumatic and fluidics flow control – the plastic diaphragm check valve.

Diaphragm check valves are widely used because they are effective and economical. They are also considered to be highly adaptable because of their design characteristics. In this post, I will provide a broad outline of plastic diaphragm check valve characteristics, function, types and materials, as well as provide some general installation tips.

Watch a short video about how diaphragm check valves work >>

It includes some live footage of diaphragm check valve testing.

Why are diaphragm check valves so widely used?

First, plastic diaphragm check valves are usually an excellent choice of check valve because they can be engineered for very low cracking pressures. In addition, because they are constructed of plastics, they are very cost effective and lightweight. One of the most useful design characteristics of this type of check valve is that there are material combination options suitable for almost any kind of process media.

CV, CVN, CVP and CVK series check valves.

What is cracking pressure?

Cracking pressure is the pressure at which a check valve begins to open and allow fluids or gases to pass through it. It is the pressure needed to open the valve – even the tiniest amount. In other words, the pressure when a check valve begins to open just a crack.

Diaphragm check valves perform the same function as all other check valves – preventing unwanted backflow.

- Protect filters from the negative effects of backflow

- Prevent process media contamination

- Control process media overflows

- Protect machinery and sensors from backflow contamination or damage

The critical element in a diaphragm check valve is the diaphragm itself. Most miniature check valve diaphragms are made of a flexible elastomeric material.

What is an elastomer?

An elastomer is any rubbery material that, when stretched or flexed repeatedly, still returns to its original shape.

Why use elastomers? Primarily function. Check valve diaphragms must flex open and then flex back to their original shapes or else be pliable enough that they repeatedly conform to the internal sealing surfaces of the check valve when there is reverse flow. Of course, a check valve needs to be reliable. Because of this, the diaphragms in diaphragm check valves are made of elastomer so that they repeatedly and consistently can perform their function.

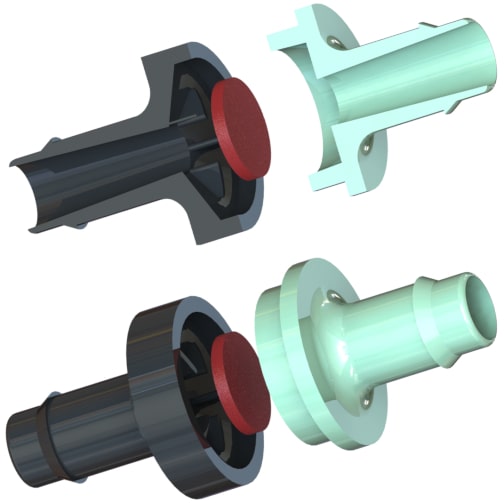

Most miniature diaphragm check valves have one of two basic designs. They are usually either a fixed flexing diaphragm or a free-floating disc diaphragm.

typical low-pressure plastic diaphragm check valve.

How does a diaphragm check valve work?

All check valves allow flow in one direction and prevent flow in the opposite direction.

How free-floating elastomeric disc diaphragms work

A self-centering flexible elastomer disc is the working part of this type of diaphragm check valve. The valve body has internal guides that keep the disc centered over the sealing surface.

The inlet port side of the valve body has a smooth curved sealing surface with a hole in its center. Backflow causes the disc to lie down across this curved sealing surface. This closes the check valve.

The outlet or exit port side of the valve body has some form of two-level seat with radiating trench channels built into it. Positive flow causes the floating disc to lie against this two-level seat. The media can then flow around the disc, through the trench channels and on out through the exit port.

How fixed flexing elastomeric diaphragms work

- Flexing elastomeric diaphragms are normally closed

- Diaphragms flex back to their original closed position when flow stops

- Diaphragm shapes usually include pleating or hinging

Figure 1 is an animation showing the open and closed working states of a check valve with a fixed flexing diaphragm. This is an ISM CVRT series check valve.

An important point about check valve installation

Because check valves provide one-way flow, it is important to install them in the correct orientation. An arrow or the symbol for a check valve (a fluidic/pneumatic logic symbol) on the outside of the body indicates flow direction. Some check valves have both the logic symbol and an arrow.

More installation tips

- Fixed flexing diaphragm check valves

- Both horizontal and vertical orientations are usually okay

- Free-floating disc diaphragm check valves

- Media with a high specific gravity or viscosity may cause the disk to float in some situations

- Orientation may cause the disc to float in some situations – please always test the orientation of the check valve in your application

Conclusion

Conclusion

Miniature plastic diaphragm check valves can be considered an economical and effective choice for flow control applications. They typically offer broad chemical compatibility options as well as very precise choices of low cracking pressure. It is no wonder there are so many miniature plastic diaphragm check valves used in such a diverse array of applications. A deeper understanding of the workings, function and materials of diaphragm check valves is important since these can be excellent components for miniature pneumatic and fluidic flow control.

For a change of pace, our upcoming blog article will look at cause marketing:

The Wild Animal Sanctuary in Kennesburg, Colorado

Have you had trouble deciding whether a plastic diaphragm check valve might be the best choice for a project? Did the option of using an elastomeric diaphragm make the choice even more difficult? How was chemical compatibility important? Help us by telling others about what you learned.