How Do Diaphragm Check Valves Work?

Last updated on December 19, 2019

Small-bore low-pressure plastic diaphragm check valves are application workhorses

An introduction to diaphragm check valves and how they work

Check valves come in a wide range of sizes and materials. They provide automatic flow control of liquids and gases using a variety of mechanisms. Small-bore low-pressure systems and vacuum systems make extensive use of diaphragm check valves. They are used to prevent reverse flow and the problems that could result from it. This post briefly describes how most small-bore low-pressure diaphragm check valves work.

Tubing or piping about two inches in diameter or smaller are frequently referred to as small-bore. Low-pressure systems are generally understood to be about 50psi (345kPa) or less.

Watch a short video about how diaphragm check valves work >>

It includes some live footage of diaphragm check valve testing.

What is a check valve?

Check valves are also called non-return valves and one-way valves. They allow flow in one direction but prevent it in the opposite direction. This undesirable reverse flow is usually called backflow. It can cause contamination, mess or malfunctions. Check valves are powered by flow and the pressure difference that exists between their inlet and outlet ports.

Learn more about the basics of miniature, compact and small-bore check valves in our check valve blog post series beginning with "Checking Out Check Valves - An Introduction".

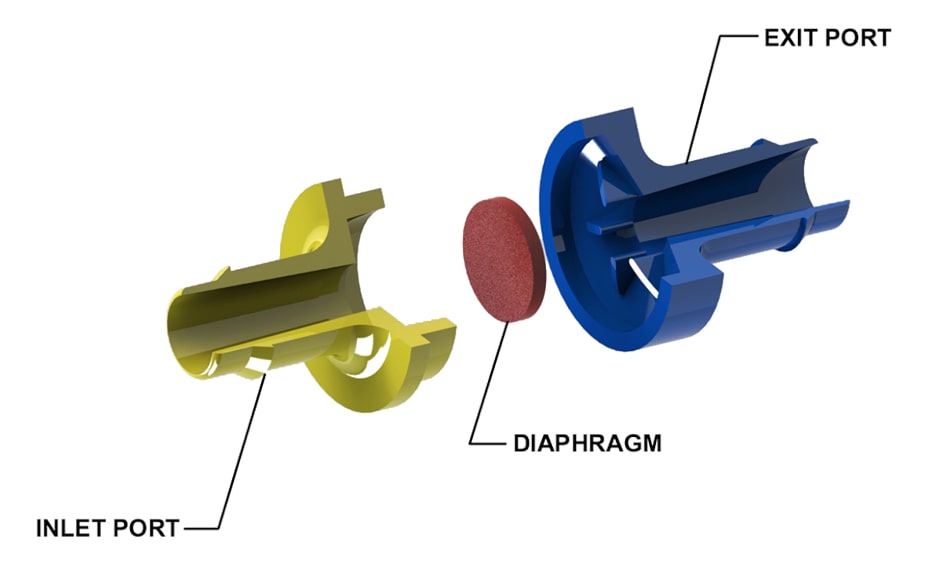

(left to right): inlet port, free-floating elastomer diaphragm disc, exit port.

What is a diaphragm check valve?

Diaphragm check valves use rubber flexing diaphragms or self-centering discs to control backflow.

Learn more about elastomeric polymers and rubbers in our blog post "Elastomers and Rubbers: What's the Difference?".

How does a diaphragm check valve work?

Free-floating elastomer disc diaphragms

These types of diaphragm check valves are almost always normally open. A self-centering flexible elastomer disc is the working part of this type of diaphragm check valve. The valve body keeps the disc centered over the seating area or sealing surface of the valve.

The sealing surface is on the inlet side of the check valve body. It has a fine, smooth surface that is usually concave or curved back towards the inlet port. There is an opening at its center. Backflow causes the flexible rubber disc to lie down across the curved sealing surface. This closes the opening to the inlet port. The closed check valve prevents upstream flow back through the inlet port.

A floating disc diaphragm check valve has a particular design on the outlet side of the valve body. Here there is usually some sort of two-level valve seat with built in channels. Positive flow towards the outlet or exit port causes the disc to lie against this seat. The media then flows around the disc, through the channels and out through the exit port of the check valve.

at rest (Normally Open), flexed diaphragm disc providing

positive flow (Open Full Flow) and reverse flow (Valve Closed).

Three tips to remember about how free-floating elastomeric disc diaphragm check valves work

- These check valves need a back pressure to close

- They depend on gravity to help close them in some low flow applications

- High viscosity or high specific gravity liquids may cause them to malfunction

working states a check valve with a

fixed flexing diaphragm. This is an

ISM CVRT series check valve.

Learn more about industrial check valve types and how they work: “How do Check Valves Function, and Why would they be Selected over other Valve Types?” at Empowering Pumps.

If you're enjoying what you're reading... please let us know by subscribing to our blog. You'll receive an email notification whenever we post a new article.

Fixed flexing elastomer diaphragms

Fixed flexing diaphragms include some form of pleating or hinging. These types of diaphragm check valves are usually normally closed. In use, positive pressure creates forward or downstream flow. This flow and the pressure behind it pushes against the diaphragm. If the pressure is high enough, the diaphragm flexes open.

As flow drops, there is a lower pressure differential across the valve. If the pressure drops low enough, the diaphragm can flex back to its original closed position. This happens when diaphragm elasticity becomes greater than positive downstream pressure.

What is cracking pressure?

Cracking pressure is the pressure where a normally closed check valve just begins to open. It is enough to allow the first trickle of fluids or gases to pass through the valve. Generally, this is considered the minimum pressure needed to open the valve.

Normally open diaphragm check valves

Most normally open diaphragm check valves require back pressure to close. Until this happens, a free-floating flexible elastomer disc allows flow through the check valve. So most free-floating disk diaphragm check valves should be considered normally open check valves.

Normally closed diaphragm check valves

Normally closed diaphragm check valves

A normally closed check valve opens when there is a large enough pressure difference between the inlet and outlet ends of the valve. When that pressure is low enough, the valve closes. The inlet pressure must overcome the diaphragm’s elasticity in order to open flexing diaphragm check valves. The diaphragm remains closed unless the inlet pressure is higher than the cracking pressure.

Conclusion

Diaphragm check valves provide durable and reliable automatic flow control. Plastic diaphragm check valves are particularly useful in low pressure and vacuum applications. This is because they are very economical and can be designed with very low cracking pressures. They also come in a variety of valve body and diaphragm materials that provide broad chemical compatibility. When matched with appropriate protective filtration, plastic diaphragm check valves are adaptable and useful.

As always, ISM offers samples to our customers as a way to assist their testing and decision-making. These can be requested when browsing our catalog.

Learn more about industrial check valve types and how they work.

Any problems figuring out if a diaphragm check valve is the right solution for your system requirements? Help us by telling others what you learned.