NRV and NRVT Series Inline Air and Gas Pressure Relief Valves

New from ISM Design - Pressure relief valves for inline flow and low clearance areas

NRV and NRVT plastic air and gas pressure relief valves

The featured new products in this post are the NRV nylon relief valves and NRVT inline relief valves. They are designed for pressure relief venting of gases, gas mixtures or vapors that do not represent health or safety risks and are not reactive under normal atmospheric conditions*.

Watch a short video featuring the NRV and NRVT plus other featured products >>

NRV and NRVT pressure check valve performance features

- Rugged nylon

- Self cleaning

- Quick opening

- Positive sealing

- Corrosion and chemical resistant

*Note: If you need to control venting of gases, gas mixtures or vapors for health or safety reasons, we recommend using an inline relief valve that directs the vented gas through piping into a containment system.

Figure 2

NRV series

pressure relief valve

About the NRV series nylon pressure relief valves

The NRV nylon pressure relief valves are designed with an integrated spring-loaded check valve or non-return valve. Their low profile is less than 25% the height of traditional pressure-relief valves for gases making them ideal for low-clearance areas. To avoid damaging the valve, follow recommended guidelines for plastic tapered pipe thread fittings installation. The inlet is on the bottom and it vents on top, exhausting directly to the atmosphere.

- Stainless steel spring

- Nylon body and check valve

- Buna-N, EPDM or Viton O-ring seal options

- Cracking pressure options (½, 1, 3, 6 or 10 psi)

- 1/8”, 1/4”, 3/8” or 1/2" male NPT pipe thread connections

Figure 2 is an NRV series miniature plastic pressure relief valve.

NRV applications and uses

- Air and gas thermal relief tank-top venting

- Atmospheric and low-pressure storage tank venting

- Gas and vapor venting of tanks, bladders or other devices

Learn more about tapered pipe threads and tapered pipe thread fittings >>

Plastic Tapered Thread Fittings Installation Guide >>

If you're enjoying what you're reading... please let us know by subscribing to our blog. You'll receive an email notification whenever we post a new article.

About the NRVT series inline pressure relief valves

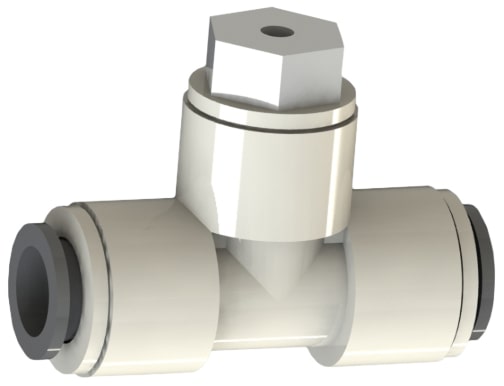

NRVT series inline pressure relief valve

NVRT inline pressure relief valves combine a tee configuration with easy push-in or push-to-connect side inlet and outlet ports. Push-in connections allow fast, easy and toolless installation and maintenance, ideal for tight spaces. These connections create a low-pressure O-ring seal on tubing. Push-in connections are suitable for nylon, polypropylene, polyethylene and polyurethane (95A) plastic as well as soft metal (copper and aluminum) tubing. The NRVT valves vent to atmosphere in overpressure conditions.

- Stainless steel spring

- Nylon relief valve body

- Acetal tee body with push-in connections

- 1/4”, 5/16”, 3/8” or 1/2” push-in connections

- Buna-N, EPDM or Viton O-ring seal options

- Cracking pressure options (½, 1, 3, 6 or 10 psi)

Figure 3 is an NRVT series miniature plastic inline pressure relief valve.

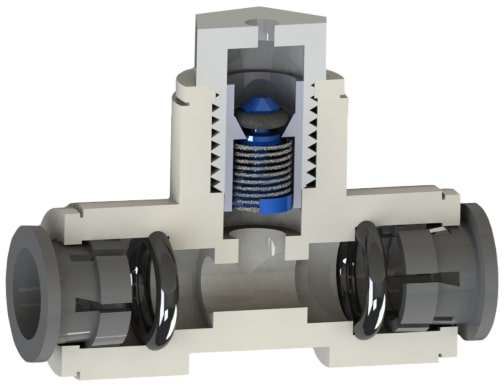

NRVT series cutaway view

NVRT applications and uses

- Gas piping inline venting

- Air, gas and vapor inline thermal relief venting

- Atmospheric low-pressure inline system venting

Made-to-order

ISM’s production department builds both NRV and NVRT series parts on a made-to-order basis so please call to confirm the time-to-ship for these parts. Volume discounts are available so please call for pricing.

Figure 4 is cutaway view of an NRVT series miniature plastic inline pressure relief valve.

Learn more about Buna-N, EPDM and Viton chemical compatibility >>

Figure 5

MEB series

nylon plastic fitting

Nylon plastic characteristics

Nylon has great strength, extremely good wear resistance and works well with air and gases. It is also resistant to sustained contact with a wide variety of chemicals. Nylon fittings and components typically work better than other thermoplastics in applications requiring higher heat resistance. Nylon is not recommended for applications where it is exposed to moisture. It is highly water absorbent and tends to swell over time.

- Good heat tolerance

- Resistant to stress cracking

- Strong and abrasion resistant

- Tough with high impact resistance

- Highly resistant to chemicals, mildew, molds and fungi

Figure 5 is a typical natural nylon plastic fitting. It is an MEB series male NPT thread by multi-barb plastic tube elbow fitting. These fittings are available with 3/16" to 1-1/2" Hose Barbs and 1/8" to 1-1/2" Male NPT pipe threads.

20AC series acetal plastic fitting

Acetal plastic characteristics

Acetal (POM) plastic components are difficult to break and are resistant to heat, chemicals and everyday wear. They work well with air, gases and liquids. Fittings made of acetal plastic are a great choice for especially tough environments.

- Good heat resistance

- Strong and lightweight

- Extremely low moisture absorption

- Very hard, rigid and abrasion resistant

- Highly resistant to chemicals, especially alcohols, oils and formaldehyde

Figure 6 is a typical natural acetal (POM) plastic fitting. It is a 20AC series quick coupling/disconnect plug fitting. These plug fittings are available in valved, non-valved, elbow and panel mount versions.

Learn more about the chemical compatibility of materials used to make flow control fittings >>

Related blog posts

Spring Loaded Check Valves – Check Valves Part III >>

A brief review of the features, uses and characteristics of miniature spring loaded check valves in air, gas and liquid flow control applications.

Elastomers and Rubbers - Is There a Difference? >>

Get the facts about differences between elastomers and rubbers. Learn about the properties of elastomeric materials that make them so useful.

Elastomers Chemical Compatibility Chart, a New Resource >>

A general guide for evaluating elastomer and rubber chemical resistance to assorted common chemicals and fluids.

If you found this article useful... please consider subscribing to our blog. You'll receive an email notification whenever we post a new article.

« Go back to the blog homepage